V-Marc : India's Leading Wire and Cable Manufacturing Brand

Download Brochure▼

+91 70555 21808

NSE Live

NSE Live

Available Color

Available in other colors as per the customer’s requirements.

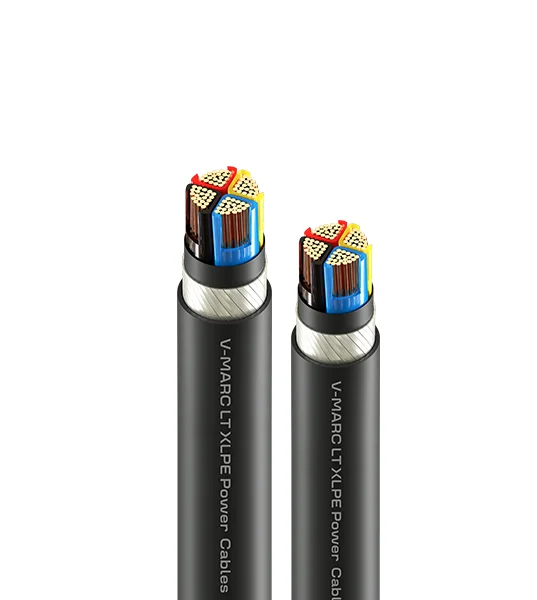

LT XLPE Power & Control Cables

CAIS-7098 (Part-1) compliant cables feature EC grade aluminium or copper conductors with XLPE insulation. They offer advantages including higher current and short circuit ratings, better resistance to moisture and chemicals, and longer service life.

Standards

IS-7098 (Part-1)

Standards

IS-7098 (Part-1)

Conductor

The Conductor of the power cable is generally made from EC grade aluminum, and annealed high-conductivity copper is used for control cables. All conductors conform to IS: 8130:1984. Power Cables with copper conductors can also be supplied as per customer requirements. The conductor is solid/stranded/bunched as per requirements.Insulation

XLPE (Cross-Linked Polyethylene)Laying Up

The cores are laid up with a suitable lay. The final layer always has a right-hand lay, i.e., if you look along the cable, the cores move to your right hand or clockwise.Inner Sheath

The Laid-Up Cores shall be provided with an inner sheath applied either by extrusion or by wrapping. The fillers and inner sheath shall be on the following:- Unvulcanised Rubber

- Thermoplastic Materials

Armouring

Armouring shall be applied over the insulation in case of single-core cables and over the inner sheath in case of twin, three, and multicore cables. The armour wires/strips shall be applied as closely as practicable. Where the calculated armouring below does not exceed 13mm. The armour shall consist of galvanised round steel wire, and where the calculated diameter below the armouring is greater than 13 mm, the armour shall consist of either galvanized round steel wire or galvanised steel strips.Outer Sheath

The PVC covering over the armouring in case of armoured cables and over the inner sheath in case of unarmoured cables is called the outer sheath. IS: 1554 specifies the nominal and minimum thickness of outer sheath for unarmoured cables and only the minimum thickness of outer sheath for armoured cables. Types of PVC compounds for outer sheath:- Outer sheath with type ST1 PVC compound as per IS: 5831, which is suitable for 70°C continuous operation.

- Outer sheath with type ST2 PVC compound as per IS: 5831, which is suitable for 85°C continuous operation.

The advantages of XLPE-insulated cables in comparison to PVC-insulated cables are as follows:

A. Technical Advantages

- Longer service life

- Low Dielectric Losses

- Higher insulation resistance

- Higher resistance to moisture

- Better resistance to chemicals

- Better Resistance to surge currents

- XLPE is thermosetting in nature; therefore, it cannot be reprocessed

- Short circuit temperature for XLPE cables is 250°C, whereas for PVC it is 160°C

- Higher current rating, higher short circuit rating, approx. 1.2 times that of PVC

- Allowable continuous operating temperature for XLPE cables is 90°C, whereas it is only 70°C for PVC cables

B. Commercial Advantages

- Due to low specific gravity, XLPE cables are lighter than PVC cables.

- Capable of carrying high current through the same cross-sectional area as compared to PVC-insulated cables.

- Lower installation charges as the diameter of the cable is comparatively smaller with a smaller bending radius, requiring less space for laying cables.

.a0c37ae14e42a8824ea3.png)